The Lockyer Valley Fruit & Vegetable Processing Company has been years in the making, but things are now starting to take shape with the purchase of a 55 hectare block which will be the site of the full-scale processing facility. The man behind this project is Colin Dorber

"We will be producing canned, juiced, frozen and powered products in the facility, it will be the only one of its kind in Queensland and only the third in Australia. We will be starting with beetroot and pineapples which are Australia's staples, then moving on to carrots, beans, onions and much more," explains Colin.

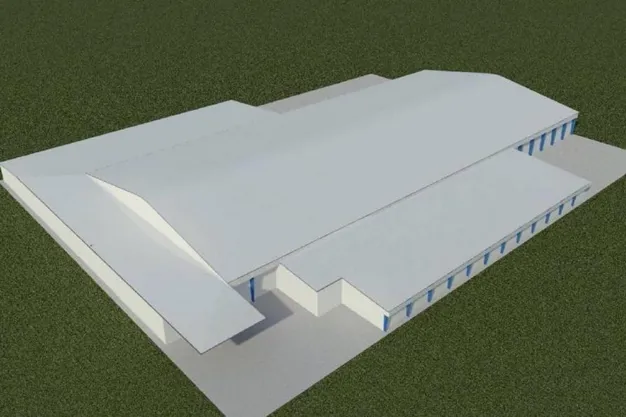

It has taken Colin 13 years to get to this stage and the aim is to produce Australian processed products just as cheaply as imported ones, "We will do this by implementing the best technology from around the world. The facility will be 1/3 the size of other processing facilities in Australia with 1/5 of the workforce. We are situated in the salad bowl of Australia, Lockyer Valley which has two crop cycles each year."

Stage one will be the cannery which should be operational in early 2026, profits from this will fund the completion of the build.

"We plan to integrate crop selection with cropping schedules to ensure that the produce is of the highest quality and yields to deliver higher ROI to growers and a steady supply of high-quality produce in a regulated and controlled delivery to match the processing capability of the factory and the volume of buffering storage on site. Integrated bulk handling systems will be implemented to enable fast discharge of produce at the processor into water to minimise handling damage, in under 5 minutes, as well as fast reloading of sanitised, empty bulk bins."

Metal cans and plastic pallets will be manufactured on site, to minimise the volume of incoming transport. manufacturing these items on site facilitates a more efficient just-in-time manufacturing profile, to closely match the crops and customers' orders. A print shop will be located on site, for cartons and labels, this will enable the integration of printing requirements with customers' orders to ensure that there is no excess unsuitably printed packaging on site.

The receivals and processing equipment have been selected to be installed in systems where produce with similar processing needs can be installed. The same group of machines will be used to process different produce throughout the year to optimise the use of these systems and machines and a thermal energy system (TES) will be installed, to make ice slurry where two hundred tonnes of ice slurry at -50oC is stored in a 200-tonne insulated silo.

There is so much in the news just now about how growers are unfairly treated by the retailers, this week it was claimed that growers are encouraged to grow too much produce and 40% of this just goes to waste. "We hope that growers will want to grow produce for us as it gives them an alternative 52 weeks of the year market for their crops. We will buy 100% of their production, regardless of quality. What can't be processed will be used to fuel the bio-mass plant which powers the plant.

"We want to replace imported canned and process vegetables with Australian grown product. We are not only looking at supplying the retailers, but also schools, hospitals, prisons etc. Eventually there may be the opportunity to export as worldwide demand for this is growing."

For more information:

For more information:

Colin Dorber

Lockyer Valley Foods

+61 410447000

[email protected]