It is more important than ever to improve shop floor efficiency. Companies are increasingly struggling to get enough staff; even more when heavy labor is involved. That is Van den Berge Handelsonderneming's experience too. This Dutch company is, thus, investing in time and labor-saving machines.

Van den Berge sorts and packages fruit and vegetable products. Patrick, Harry, and Artjan van den Berge run this family business. "We began as an onion packing plant. Over the years, we've added sorting and packing of other products, like celeriac, carrots, red beets, and parsnips. But, at about 70%, onions still hold the largest share," begins Artjan.

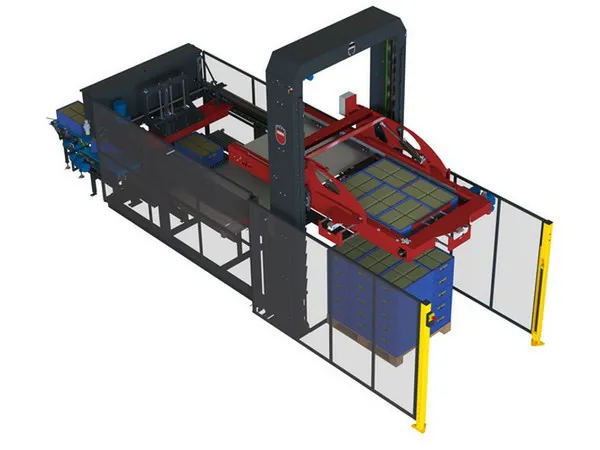

Automating crate stacking

Van den Berge's sorts and packaging onions it gets, in bulk, directly from growers. Once packaged, the products are stacked on pallets. "Many leave in pool crates, which are quite heavy once full. Such heavy manual labor is actually out of the question. To spare our people, we've bought a palletizer that automatically stacks boxes and crates on the pallets."

Van den Berge chose a Burg Machines Top-Line palletizer. "What was the deciding factor for us? We wanted a compact, reliable, high-capacity machine. The palletizer must run smoothly all day and be easily operated by anyone. We wanted to be able to choose different stacking patterns, too, because we use the machine for different products and packages. Plus, their palletizer was quickly available, and we've had good experiences with Burg Machines," says Artjan.

Doing more work in less time

Last year, they began using the new machine, which can average about 1,000 boxes and crates per hour, to their full satisfaction. "Normally, you'd need four to five people for that; now we get by with two. So, it's very efficient. We want to soon increase that efficiency by linking the machine to two weighers."

This family business has been improving the production line for some time. By automating more of it, they can reduce the high labor costs and do more work in less time. This is not the first time Van den Berge has done business with Burg Machines. They bought a box tipper from Burg Machines, and the engineering firm was also closely involved in realizing Van den Berg's new washing line.

"They're familiar with the field, listen carefully to our wishes, and closely consider our company's needs. Things like how do we work? Where are our people on the shop floor? What are the logistics like? You must look at these important aspects when buying and installing different machines," Artjan explains.

Growing palletizer market

Burg Machines's Arjan van Burg agrees: "It's all about the added value. We'd rather not sell machines if that investment doesn't benefit the customer. Working as efficiently as possible with fewer people is becoming increasingly important. Good labor is scarce, and you want to keep the people you have for as long as possible. That's why it's paramount to lighten heavy physical labor wherever possible."

There is, thus, an increasing demand for palletizers, which is a good development. Much of the sector's stacking is still done by hand, which takes a toll on people. "A palletizer saves on personnel, relieves heavy work, and improves capacity," says Arjan. "The plate palletizer, which Van den Berge also chose, is currently the preferred option. It's a compact, smart machine that's user-friendly and offers many different stacking patterns possibilities."

Besides machines that automatically stack crates on a pallet, crate handlers are another growth market for Burg Machines. "That, too, is somewhat more strenuous work that is also often being automated. That saves plenty of time and labor without compromising product quality. The great thing is that this investment immediately gives companies added value," Arjan concludes

For more information:

Burg Machinery

Weihoek 11

4416 PX Kruiningen

Tel: +31 (0)113 50 13 73

avanburg@burgmachinery.com

www.burgmachinery.com