Proseal’s ability to deliver fast, efficient, and reliable tray sealing solutions for the fresh produce sector, while helping growers and processors meet their sustainability goals and commitments will be the central theme of the company’s participation at this year’s Fruit Attraction exhibition.

Proseal has been at the forefront of the introduction of new recyclable and compostable trays and film alternatives to plastic. Recent introductions have included the Stackpack, a premium, craft-board tray that can be stacked in multiple layers without any damage to produce and which is 100 percent recyclable. The company has been instrumental in the development of a solution that enables the flanges of the tray to be folded and sealed while running on inline and semi-automatic machines.

Another example is the CKF Earthcycle Punnet, which provides the option to swap between plastic and pulp, as well as the chance to move from plastic-based to cellulose-based film.

Importantly, many of these new formats can utilize existing tool sets in order to minimize investment. As Proseal develops new features to meet market requirements, these can also be retrofitted to existing models already in operation. This allows fruit growers and packers to keep up to date with changing consumer and retailer demands without the need to invest in new equipment.

Proseal tray sealing technology can also help companies tackle the problem of food waste, another major environmental challenge. Top sealed trays protect produce in transit throughout the supply chain while the availability of MAP (Modified Atmosphere Packaging) extends product shelf life.

In addition, trays can be sealed with pre-printed film and fully integrated online printers, which eliminates the need for additional labels and applicator equipment (and therefore add-on costs) while helping to improve the packs’ overall appearance. This process seamlessly combines the sealing, bar-code / use-by-date-printing, and brand identification process into one single action.

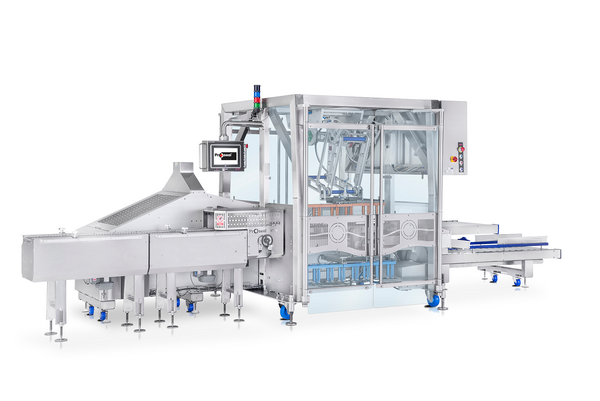

For the first time, Proseal will be showcasing its advanced CP2™ case packaging machine at the exhibition, which combines efficient power consumption and a compact footprint with the ability to handle a wide variety of tray and pot formats, including the latest sustainable options.

The CP2™ can fill cases at up to 110 packs per minute. Key to this performance is Proseal’s proven ProMotion™ tray infeed system, which maximizes throughput by using following motion and intelligent buffering technology to effectively control the flow of trays, enabling them to feed continuously into the machines without stopping.

The Proseal stand will also showcase the capabilities of its parent company JBT in fruit and vegetable processing, underlining its ability to provide complete solutions for the production and packaging of fresh produce, Stand 10C15A, Area I. Auxiliar, Hall 10.

For more information:

Proseal UK Ltd

Tel: +44 (0) 1625 856600

Email: [email protected]

www.proseal.com