Mushroom farms around the world are dealing with the problem of labor shortage. In Canada and the US, there is a labor gap of about 20 percent and about $200 million worth of mushrooms are wasted each year due to the lack of laborers. “It’s a skilled job as mushrooms are very delicate to the touch” says Michael Curry with Mycionics, developer of a robotic mushroom harvesting system. “It takes about three months to become a skilled harvester but due to the repetitive nature of the work and the high humidity, it’s a job people are not as keen to do.” With a turnover of 40+ percent, many workers leave the farm before they have learned the ropes.

Labor shortage is one of the key drivers of the development of a robotic mushroom harvesting system. “Mushroom farms are well suited for automation,” said Curry. “They operate all year round and have a common infrastructure.” The Dutch aluminum shelving system is about six to seven shelves high and it’s the most widely used shelving technology around the world. “This is another good trade for robotics as there is no need to change the infrastructure.” In addition, mushrooms grow very quickly, at a rate of 4 percent per hour, and they need to be consistently harvested at around 55 mm in size for optimal yield.

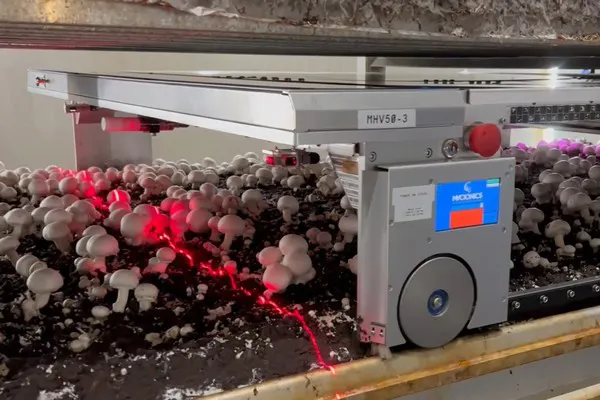

Robotically picking white mushrooms.

Robotically picking white mushrooms.

Digitization

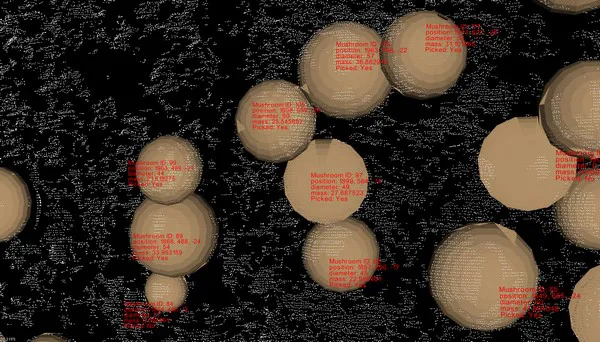

All these traits played a key role in the development of a robotic system that mimics the way humans harvest mushrooms. Mycionics’ harvesting system digitizes the crop as it scans the beds and can identify 98 percent of the mushrooms. Data like location, size, temperature, humidity, CO2 levels are collected and processed. “It takes the system about 30 minutes to scan a large bed containing up to 200,000 mushrooms or more.” Based on the results of the scan, an overall harvesting strategy is determined, and the system will tell itself where to start harvesting on the bed. “The system harvests each mushroom at the optimal time and size, which is called graze harvesting.” While growing mushrooms used to be more of an art, the availability of crop and climate data and the use of robots is making it more scientific.

Mushrooms being scanned.

Mushrooms being scanned.

Digital representation of mushrooms.

Digital representation of mushrooms.

Benefits

Not only does the robotic mushroom harvester help solve labor issues, it also generates a potential yield improvement of about 10 percent. First of all, digitization of the crop results in the mushrooms being picked at exactly the right time. Human laborers work in 8 to 12-hour shifts while the robotic system harvests continuously around the clock, allowing mushrooms to be picked at the optimal harvest time and size. In addition, the system allows for stems to be trimmed consistently.

“They are cut straight and at the exact right length, resulting in a maximum stem length and maximizing weight of the product,” commented Curry. This results in a yield improvement of about three percent. Last but not least, mushrooms are weighed and put in punnets. Since they can’t be short weight, there is usually a small overage. “With human harvesting, the overage is about three to five percent,” said Curry. “Due to their consistency in size, overage is reduced to about one percent with robotic harvesting.” Mushrooms are picked without damage as the technology was designed to avoid contact with the top of the mushroom cap.

Since the fall of 2022, six robotic mushroom harvesters have been operating on a farm in Ontario, Canada. Mycionics is the first company globally to robotically pick mushrooms and has already received interest from other mushroom growers in Canada as well as the US, Europe, and Australia. Currently, the company is in conversations with two other mushroom farms in Ontario, Canada for the installation of harvesting robots and expects to install them this year. The company won’t be immediately selling their robotic technology but instead offers a picking service. “We get paid per kilogram of mushrooms that we successfully harvest, which allows all sizes of farms to get access to robotic harvesting to help with the labor shortage.”

Click below for a video of a mushroom harvester operating on a farm in Ontario, Canada.

For more information:

For more information:

Michael Curry

Mycionics Inc.

mcurry@mycionics.com

www.mycionics.com