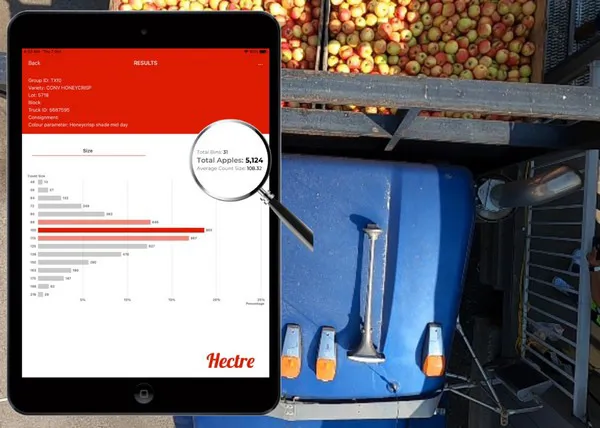

Hectre have released their transformative Spectre Top Down app to seven select US apple receiving sites. This enables high volume packhouses to quickly size more than 5,000 apples straight off the truck, with no touch on the fruit.

Huge size samples are being captured straight off the top of trucks

Huge size samples are being captured straight off the top of trucks

Spectre Top Down combines Hectre’s early fruit sizing computer vision app, Spectre, with a simple camera installation. As trucks pass under the camera, Spectre detects and sizes more than 100 apples from each bin on the top layer of the truck, delivering a massive increase in early size data, which is shareable via CSV or API to QC, scheduling and sales teams.

Washington fruit leader Sage Fruit were the first to gain the benefits of Hectre’s Spectre Top Down technology, and played a key role in its development.

"With Hectre's Spectre Top Down app, we can capture size data on more than 5,000 apples from just one truck pass. That delivers a massive increase in our size sampling where reliable data is crucial,” notes Nicole Gordy, Director of Business Analytics at Sage Fruit.

Hectre provides the camera which is all that’s needed to connect

Hectre provides the camera which is all that’s needed to connect

Sage Fruit grows, packs, and ships mostly apples, pears, and cherries. In 2021 they began using Hectre’s mobile fruit sizing app, Spectre hand-held, which sizes fruit in bins in the packhouse or orchard, in seconds, from just a standard iPad.

"Our team identified the advantages of Hectre's fruit sizing technology early on and have partnered closely with them throughout its evolution. Gaining size and color data at the earliest point in our process means we can arm our packhouse and sales teams with the information they need to optimize our pack operation and sales fulfillment,” adds Gordy.

Monson Fruit is another premier packer that quickly signed up for the truck top tech. Jaritt Hays from Monson Fruit notes they’re gaining numerous advantages from the app. “It would take a full team of ten people, a week to manually size the volume of apples we now get from Spectre Top Down in a single day. With these big size samples, we can identify the best time to hit the market for that fruit to gain the highest return. We can provide our sales teams with better projections and they can rely on us having the fruit when they take orders.”

Reducing unnecessary costs is another benefit Monson Fruit have recognized. “Better size data from these big samples means we can reduce pack line stoppages, which are so costly. Without reliable early size data you might set up to run one size and then you have to make a bunch of changes to another size. You might have 100 people that you’re paying, just standing around waiting for decisions and adjustments to be made. We really want to avoid that,” adds Hays

For more information:

Kylie Hall

Hectre

Tel: +64274198322

Email: kylie@hectre.com

www.hectre.com