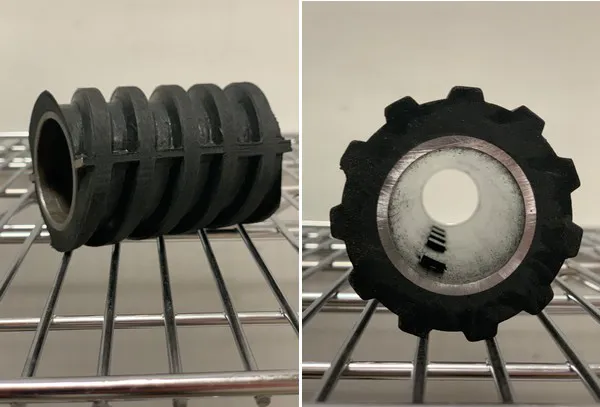

PROEX FOOD announces the official release of its HUSKER ROLLS. These rolls are critical for sweet corn and seed corn processors and the rolls work with all OEM huskers and ship quickly.

“Together with the official launch of our iNTELLIPRO™ HUSKER, we are also addressing a common market need. Sweet and seed corn processors need high-quality rolls that ship fast and we are now fulfilling that need,” said Nick Maglio, director of marketing at PROEX FOOD.

PROEX FOOD says fast delivery is easily available for roll shipments.

“We pride ourselves on our commitment to serving our customers,” said Ross Lund, CEO of PROEX FOOD. “We are committed to delivering efficient line solutions with the right technologies, then supporting our customers long-term with quality spare parts. Husker rolls are part of that mix. Common rolls are in stock and custom roll orders ship quickly. Customers who have already switched to our rolls are happy with their performance and with how fast they received their parts.”

PROEX FOOD also offers engineering knowledge for processors and its engineers strive to help processors optimize their lines.

“We promote our Optimization Process for custom line design and installs, and that methodology applies here as well,” said Daniel Ghadiri, president & CTO at PROEX FOOD. “There are now more groove, blade and material options than ever before and our rolls benefit from many years of real-world use and design improvements. We are happy to discuss options for the right roll bed configuration for a specific crop and final product conditions. Until that happens, processors are not yet as efficient as they should be. Just because a specific pattern has been used for years doesn’t mean it’s the best one. We also work with our customers to achieve maximum efficiency.”

The PROEX FOOD HUSKER ROLL catalog can be found on its parts page or by talking to a company representative

For more information:

For more information:

Nick Maglio

Proex Food

Americas / Australia / New Zealand: +1 414 626 5741

UK / Europe / International: +48 22 185 75 87

marketing@proexfood.com

parts@proexfood.com

https://www.proexfood.com/