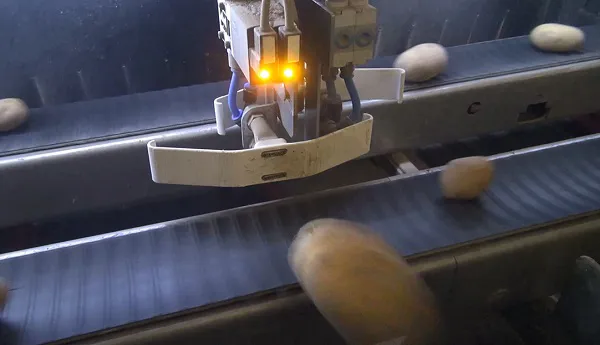

The Smart Grader is an optical grader that uses advanced camera technology. It sorts by size, shape, and visible characteristics like cracks, green areas, bumps, and scab and wireworm damage. "It's the best way to grade potatoes and onions," says Wouter Blok of the Dutch company GeJo Grading.

"In seed potatoes, size accuracy is vital. Precision size grading is thus immediately profitable."

"In seed potatoes, size accuracy is vital. Precision size grading is thus immediately profitable."

Camera technology with consistent precision

The Smart Grader EVO is built modularly with two or four sorting belts, allowing for an eight or 12 grading-belt setup. Most machines are delivered with eight outputs. "Users can use Ellipse software to specify the exact desired grading sizes and quality classes. For seed potatoes, size accuracy is vital. You can only sell the main size as seed potatoes; the larger and smaller ones go directly to consumption."

"The Smart Grader is so product friendly; it can cold-sort with zero damage risk."

"The Smart Grader is so product friendly; it can cold-sort with zero damage risk."

"Very accurate size grading is thus immediately profitable. Another important feature is accurate quality grading. Visibly defective products are easily recognized and separated. That saves considerable labor and ensures improved sorting quality continuity. After all, the machine doesn't get tired; it's always sharp. So you get a better end product," continues Wouter.

According to him, the machine product's friendliness and cold-sorting ability are other advantages. "Products are usually warmed up first. So, this saves energy. Several Smart Graders are already running at large seed potato growers in the Netherlands, Denmark, Scotland, and France. In Germany, arable farmers who sell ware potatoes and onions locally use the machines too. They use them every day to sort, pack, and deliver. And in Switzerland, we have a customer who grades sweet potatoes with it."

Rapid, precise sampling

A few years ago, the Smart Grader gained a younger brother: the READER. This compact, mobile reading unit analyzes and records samples. It measures length and diameter, calculates square measure, volume and weight, and counts the number of potatoes or onions. This device needs only 20 seconds to sample ten kilograms. The final report appears directly on your smartphone or laptop.

It can be delivered with the batch to the buyer too. "Seed potato growers can take this compact machine to their field for trial harvests. The samples then don't have to leave the field, which prevents contamination. Trading houses and research facilities often use the READER to check batches," Wouter concludes.

Wouter Blok

wouter@gejograding.nl

![]() GeJo Grading Services

GeJo Grading Services

Lindeweg 24

8315 RD Luttelgeest

+31 (0)6 223 01963

info@gejograding.nl

www.gejograding.nl