Sustainability is a key megatrend that is changing the face of produce packaging, influenced by three intertwined market drivers.

Today’s shoppers are increasingly concerned about the environment. Mintel’s 2022 Sustainability Barometer found that periods of prolonged extreme weather across Europe have placed environmental issues into sharper focus for European consumers. The report showed that the number of consumers concerned about climate change increased by 7% compared to 2021, while a third of consumers worldwide were deeply concerned about plastic pollution.

As a result of increased pressure from consumers and in reflection of their own sustainability pledges, many brands and retailers are looking to transition away from plastic packaging to more sustainable alternatives.

And lawmakers are beginning to act, making this transition a legal imperative. In 2023, Spain will ban plastic produce packaging on all fruit and vegetables weighing less than 1.5kg. Legislation came into force in France this year, which banned plastic wrapping on 30 types of fruit and vegetables, including staple foods like bananas, peppers, and apples. While soft fruits and cherry tomatoes are not currently covered by the ban (retailers have been given longer to find alternatives for these products), all plastic packaging for whole fruits and vegetables will be in-scope by 2026.

These drivers are motivating many growers and packers to transition away from plastic packaging to fibre-based alternatives, meeting the needs of legislation, their customers, and in turn, the desires of their consumers.

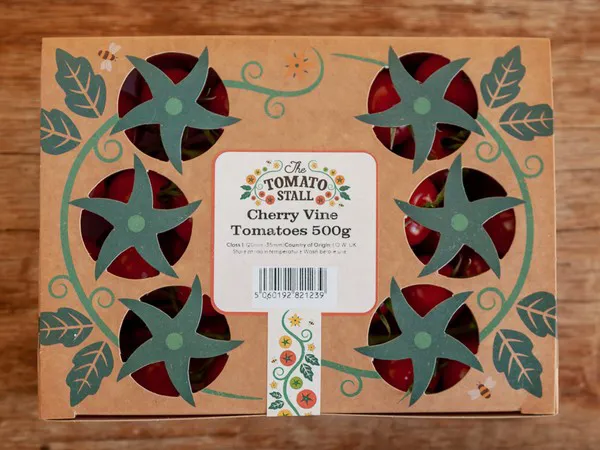

A successful example of this approach is UK-based tomato producer, The Tomato Stall, who wanted to carry its ethos around sustainable tomato production through to its choice of packaging. The producer partnered with Graphic Packaging International to replace their previous flow-wrapped tray with a 100% fibre-based alternative.

With a ‘first-to-market’ design, Graphic Packaging developed a solution that afforded the same level of protection as the previous pack and could withstand chilled storage, without compromising product freshness. This move to a fibre-based pack significantly reduced the amount of plastic in The Tomato Stall’s overall portfolio, while at the same time, creating a stand-out, more visually appealing pack.

US-based apple distributor Belle Harvest partnered with Graphic Packaging to create new recyclable cartonboard packaging for their premium apple ranges that was not only functional and aesthetically pleasing but offered equivalent performance in terms of product protection and freshness.

Following implementation, Belle Harvest reported that the cartonboard pack actually offered the apples better protection from bruising during transport and storage, reducing apple defects by around 15%.

By engaging in a collaborative approach with an expert in fibre-based packaging, producers can effectively overhaul their packaging to be more sustainable, while still being efficient in the supply chain and desirable to consumers.

This approach future-proofs the produce category against the increasing anti-plastic stance among consumers and lawmakers but, most importantly, each successful fibre-based packaging solution is an important step towards reducing the world’s reliance on plastic.

PHD Marketing Limited

Tel: +441977708643

[email protected]