After the withdrawal from the market of some batches of chicken frankfurters which resulted positive for Listeria and the more recent withdrawal of salmon sandwiches, people have been increasingly discussing the microbiological contamination of food. Fresh produce and "ready to eat" products are not exempt from risk.

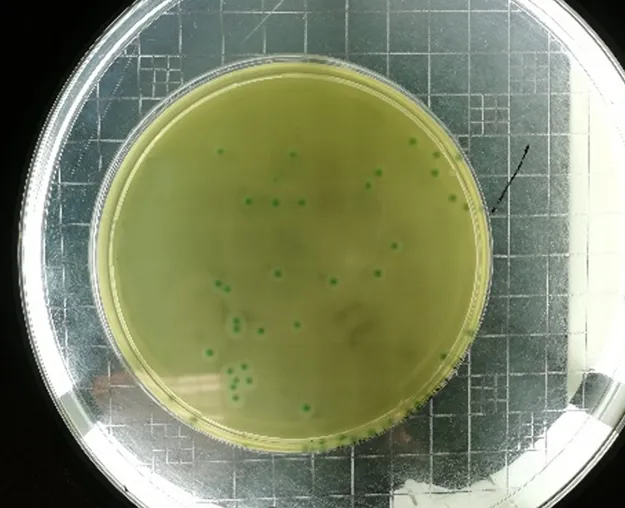

Listeria Monocytogenes: green colonies surrounded by an opaque halo

Listeria Monocytogenes: green colonies surrounded by an opaque halo

"The presence of Listeria largely affects agricultural products too, as it can be present in the soil and water, thus contaminating fresh fruits and vegetables, fresh-cut or frozen products. This bacteria can in fact survive and multiply even at low temperatures. To get an idea of how widespread the problem is, just think that contamination can occur for food throughout all production, handling, storing and distribution phases on both an industrial and domestic level," commented Marzia Arborea from Agro.Biolab Laboratory.

"Ready-to-eat foods are certainly more exposed to contamination due to their chemical and physical characteristics and because of their long commercial life that enables pathogens to proliferate, reaching concentration levels that can cause an infection. The frequency and severity of the symptoms of microbiological contamination, especially in the case of Listeria, is such that operators have identified procedures to reduce the risk of contamination."

Microbiological analysis of food, preparation of a sample

Microbiological analysis of food, preparation of a sample

"Such procedures involve the cleaning and disinfection of the production environment, but also checks on water, the monitoring of the temperature throughout the various processing phases as well as clear indications on the label reporting the need, for some products, to cook them, as it is the only way to inactivate the bacteria. Agro.Biolab Laboratory is a qualified partner for microbiological checks as well."

"Our laboratories boast the competence and experience of specialized partners to offer specific analytical services to check food, the water used for processing, work surfaces and environments according to the legislation and national and international standards AFNOR, AOAC, ISO, APAT".

Agro.Biolab Laboratory holds the ISO 17025 certification and follows the strictest protocols to ensure the accuracy of the results transmitted and the independence of its operations.

For further information:

Agro.Biolab Laboratory s.r.l.

S.P. 240 Km 13,800

70018 Rutigliano (Ba)

+39 080.477.07.62

www.agrobiolabitalia.it