By spending years studying the frozen food processing market, OctoFrost developed a turnkey solution for the frozen food processors; an IQF Freezer with patented bedplate technology. This type of technology is unique to OctoFrost alone and offers several advantages to its customers, the marketing coordinator of the company states.

IQF stands for 'Individually Quick Frozen', as each individual piece of food is quickly frozen individually. “It is a well-known and efficient technology used for quick freezing products such as fruits, vegetables, tropical fruits, berries, seafood, poultry, meat, dairy, and pasta,” says Sana Rehman, marketing coordinator for OctoFrost. “This is the most common method of freezing smaller food items – resulting in a higher quality, natural looking IQF product even after defrosting.”

While most traditional IQF freezers use a metal mesh belt to transport and fluidize the product, OctoFrost uses an exchangeable bedplate instead, Rehman explains. “There are a number of advantages for doing so. The bedplates are perforated for excellent fluidization and for achieving optimal aerodynamics inside the freezer. This, together with the adjustable movements of the OctoFrost bedplates, ensures that the individual pieces of the product remain separate during the freeing process. As a result, IQF food processors get a premium, loose product that is easier to work with, instead of a large, frozen lump of product.”

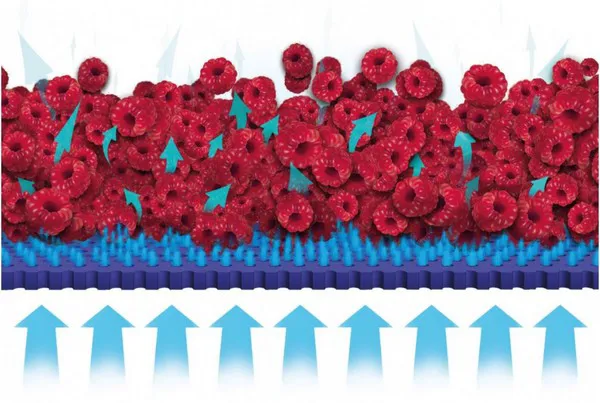

In order to achieve a well separated frozen product, processors will need one key element – fluidization. “Fluidization refers to when a product acts like a fluid inside of the freezer. This happens with the help of an upward airstream created with the movements of the bedplates, separating the product during the freezing process. Fluidization is also proven to minimize crumbling in tricky products such as raspberries.”

“There are four main elements that influence fluidization: The air pressure built up under the bedplate by the fans, the actual bedplate configuration (thickness, the material used, and the holes), the bedplate movement (which can either shake or vibrate) and finally the product characteristics, such as product size, water content, texture and so on.”

All of these elements are taken into consideration when setting the optimal configuration for the type of product being frozen, contributing to food safety, natural appearance, energy efficiency, and a high yield. Each of these benefits is a direct result of the design features and technology of the OctoFrost IQF freezer. For instance, the natural appearance of the frozen products is possible due to the gentle fluidization on the OctoFrost bedplates which use asymmetrical movement to gently separate the products and efficiently freeze them.

However, there are certain pitfalls to avoid in order to achieve optimal fluidization, Rehman says: “Dead zones on the bedplates where the product doesn’t move at all, excessive turbulence, which can damage fragile products or even blow the product away from the product zone and too little movement of the product on the bedplates are major things to look out for.”

For more information:

OctoFrost Group

Email: [email protected]

www.octofrost.com