Although a multitude of packaging innovations are introduced to the market every year, flowpacks still remain common for many fruit and vegetable products. For over 30 years, the name Barsch has stood for high-quality flowpack machines. At Fruit Logistica, the company presented the latest sustainable plant technology in flowpacks.

Frank Lindenstruth and Nadine Barsch at this year's Fruit Logistica.

More sustainability in packaging

At Fruit Logistica, the focus was particularly on the new packaging line for flowpacks with cellulose viewing windows. Ms. Barsch: "We developed this process in close cooperation with the company Lorentzen & Sievers. With this system, we are killing several birds with one stone: first, because the viewing window made of wood-based cellulose meets the trend toward more sustainability in packaging. Second, because the consumer wants to check the freshness of the respective product at the POS, which in turn is made possible by the transparent packaging solution." The process is well received by organic packers, among others, adds Ms. Barsch.

The new packaging system from Barsch can be used for almost all fruit and vegetable products, she adds. Barsch: "We have already received a lot of inquiries, but the actual implementation in practice is, unfortunately, lagging behind somewhat because everyone is waiting for a final decision from the trade. Everyone is trying to keep their finger on the pulse of new packaging solutions, which is why the range of products on offer has been expanded enormously. On the other hand, there is still no solution whatsoever that meets all requirements."

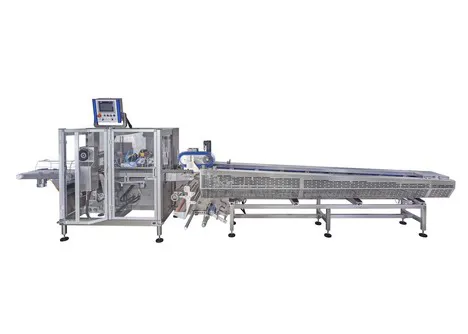

The latest flowpack machine for loose fruit and vegetables

Packaging reduction and avoidance

If the decision is made to use packaging, flowpacks are still highly suitable, according to Barsch. "First, today's flowpacks use very little material, which is in line with the trend towards packaging reduction and avoidance. Second, the associated machines are quick to convert to different sizes and are easy to operate."

Although Barsch is now represented in several segments, flowpack machines for fruit and vegetables remain the company's core competence, accounting for around 80 percent of sales. "We have built up a high referral rate in our core business. Nevertheless, the fruit and vegetable business is quite seasonal. From December to April, for example, so we are looking at other areas as well. A growing business is the rental and sale of used machinery, for example, to lateral and new entrants who want to package their produce in line with market requirements," Barsch concludes.

For more information:

Nadine Barsch

Barsch GmbH & Co. KG

Burkhardsfelder Str. 19

35447 Reiskirchen

Tel: 06408 969470

info@barsch.co

www.barsch.co