Industrial tomatoes are one of the most valuable references in the fruit and vegetable sector, especially if they are related to particularly valuable products such as, for example, the Pachino PGI tomato. The Pachino tomato is one of Italy's top agri-food products due to its high sensorial and nutritional properties, which are an expression of its territory of origin. In order to ensure the high quality of the product destined for the fresh market, the fruit is rigorously selected both in the field and in the warehouse, which generates a production waste that once was not even considered as usable for the production of derivatives such as tomato paste, juice, sauce, puree and ketchup.

Paolo Rapisarda, a researcher at Crea-OFA in Acireale (CT), spoke about “several existing studies that are moving in the direction of identifying technological solutions and innovative formulations, in order to put tomato derivatives on the market that are increasingly appreciated by consumers,” during a conference on Pachino tomatoes PGI.

Dr. Paolo Rapisarda

Dr. Paolo Rapisarda

"Only 5%, or 16,000 tons, of the total production of tomatoes in Sicily is destined for processing. This is a very low percentage, due to the fact that most of the product for processing is the result of a selection based on commercial needs (for mere aesthetic defects), with good quality fruit.”

The total tomato production in Sicily comes from an extension of 15 thousand hectares, 3 thousands of which come from cultivation in cold greenhouses (i.e., unheated, therefore much more sustainable than those in central Europe - Ed). Together they account for 417,000 tons per year (UniCT data, average for 2016/2020), of which only about half is grown in open field, with much lower yields (compared to greenhouse production) per square meter.

The total tomato production in Sicily comes from an extension of 15 thousand hectares, 3 thousands of which come from cultivation in cold greenhouses (i.e., unheated, therefore much more sustainable than those in central Europe - Ed). Together they account for 417,000 tons per year (UniCT data, average for 2016/2020), of which only about half is grown in open field, with much lower yields (compared to greenhouse production) per square meter.

"By-products mainly consist of skins and seeds. These residues, if not properly treated, become waste, generating problems of disposal, environmental pollution and a significant increase in processing costs,” added Rapisarda.

"By-products mainly consist of skins and seeds. These residues, if not properly treated, become waste, generating problems of disposal, environmental pollution and a significant increase in processing costs,” added Rapisarda.

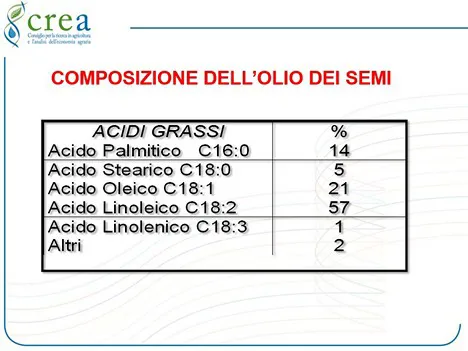

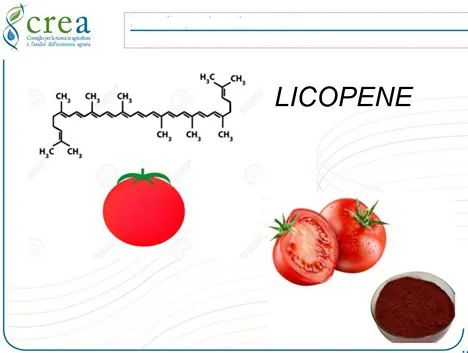

"Therefore, a new segment of the supply chain needs to be introduced, which should provide a rational use of by-products for the production of high added-value substances such as phenols, lycopene, oil from seeds, etc., for use in the food, cosmetics and pharmaceutical industries," continued Rapisarda.

"Therefore, a new segment of the supply chain needs to be introduced, which should provide a rational use of by-products for the production of high added-value substances such as phenols, lycopene, oil from seeds, etc., for use in the food, cosmetics and pharmaceutical industries," continued Rapisarda.

Above: Lycopene. In the slide below: practical applications of lycopene extracted from tomatoes.

Above: Lycopene. In the slide below: practical applications of lycopene extracted from tomatoes.

"Further aspects to be taken into account in the circular economy are the use of waste in the feed industry and energy applications, i.e., anaerobic digestion for the production of methane," concluded Rapisarda.

For more information:

Paolo Rapisarda

Crea – OFA di Acireale

+39 3479197756

paolo.rapisarda@crea.gov.it