Although the price of ready-to-eat mangos is a bit more expensive than fresh raw fruits, market demand is still increasing in many regions. This trend brings a market opportunity for Astra, an innovative Japanese producer of peelers.

A compact mango peeler with high efficiency

Ryo Takeshita is the sales manager at Astra, “We see a steady increase of ready-to-eat mangos in many countries. These products are peeled and cut into pieces, and sold in small sealed packages with a weight between 200g-500g. People like to buy them as mangos are often very juicy, and not easy to be peeled by hand. Furthermore, the most popular varieties such as Kent are often too big to consume by one person, so consumers rather buy the ready-to-eat mango pieces that they can share with others.”

“For big chain stores, most often such ready-to-eat packages are first processed in processing factories, and then shipped to retail stores. But the problem is, mangos are quite perishable. When kept on the shelf for a longer time, or when the surrounding temperature changes during processing or in transport, the quality of the cut fruits deteriorates and the fruits easily rot. This not only results in food waste, but may also lead to consumer complaints.” Ryo said.

“So as a peeler innovator, we started to think how we can provide an easier solution, so that retail consumers can easily eat freshly peeled mangos for a lower price. We invented our first mango peeler series 2 years ago. The machine is very compact, highly efficient, and suitable for small-scale retail stores with a single peeler, or IQF factories with multiple peelers.”

Astra developed different models for peeling mangos with various sizes. “Take the Kent mango for instance, this variety is quite large and can grow up to 500 grams. So for Kent, our KA-750 model is most suitable. Users can also use the same model to peel large size fruits such as pineapples and melons. Some other varieties such as the Tainong (Irwin) Mango are smaller, for such small mangos KA-700H series are most suitable. Users can use this model for all small size fruits such as oranges, kiwis and apples.” Ryo said.

“We aim to help retailers boost sales of ready-to-eat fruits”

“As a peeler innovator, we aim to help retailers increase the productivity of ready-to-eat fruits, while saving on their labor cost. Of course, we also want to help retail boost their sales, by presenting the beautifully peeled, ready-to-eat fruits to consumers.”

Ryo shared a story of his recent client from California, a supermarket that newly used their KA-750 and KA-700H mango peelers. “The original protocol of this supermarket for mango processing, was 4 people working 5 days/ week with 8 hours/ day, which means 160 labor hours. After using our mango peeler, it was possible for them to peel the same number of mangoes with a 3-man team, working 5 days/week with 5.5 hours/day, which is only 82.5 labor hours. This is nearly 50% of the work week given back to redistribute labor or reduce labor costs. The cost of the machines was earned back in 2 months, which was great news for this supermarket.” Ryo said. “Automatic peeling is more hygienic compared with manual peeling, especially during the covid-19 pandemic consumers are more conscious of their health. The Astra peeling methods gives more safety to the supermarkets.”

“The story of this California supermarket is not an exception, we also received similar feedback from a Japanese supermarket who used our machine for pineapples, that their sales of fresh-cut pineapples increased by 30%.” Ryo said.

User-friendly technology with better peeling performance

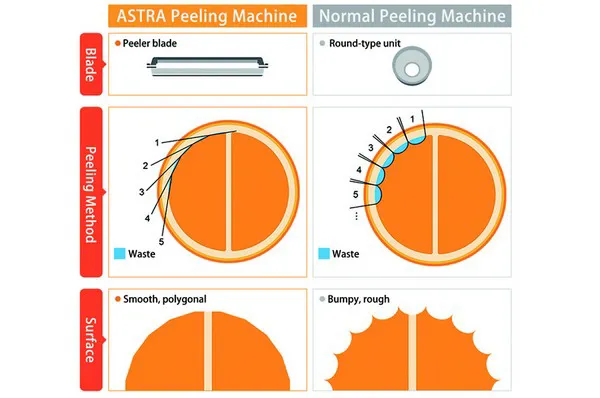

Compared with traditional ‘round-type peelers’, the Astra ‘blade peeler’ generates a variety of benefits with regards to peeling performance. “First of all, the fruits’ peeling surface is much smoother than round-type peelers, which leave the pulp surface very bumpy and rough. This results in low pulp waste and fewer juice drippings. Also because of the smoother surface, the fruit has a longer shelf life and can keep fresh for a longer period. Secondly, the straight blade performs faster with high accuracy, which results in a better yield rate.” Ryo said.

“Most importantly, users can easily adjust the peeling depth and select the most suitable program for certain types of fruit. No matter how thick or thin the fruit peel is, from thick-skinned oranges to thin-skinned lemons, the blade peeler will provide the best performance accordingly.”

Though the principle behind the peeler is quite complicated, the machine itself is designed in a very user-friendly way. “The machine is pre-programmed, all users need to do is attach the fruit to the peeler, choose a program, and press start. The peeling speed can be up to 400 pieces/hour (≈9 seconds/piece). With an adjustable peeling depth, the blade can handle fruit skin from ‘paper-thin’ till ‘cardboard-thick’.” Ryo introduced.

Growing demand worldwide

Astra invented the mango peeler in 2019. The model has spread around the world very quickly. “This year, we sold almost double the amount of units compared with last year. In the beginning we had a difficult time to be recognized by the customers. But now many distributors around the world see the market potential of the model and help us to make this model more well known.” Ryo said.

“Among all markets, the demand from Taiwan is increasing steadily. Taiwan has a flourishing mango industry, and the market was already familiar with Astra from our pineapple peeler model, so we quickly sold many models to this market. Besides Taiwan, South Asian and South-East Asian countries also have great potential for our low-priced mango peeler model.”

Over the past 20 years, Astra has been fully dedicated to automatic peeler innovation. The company has received several awards related to automatic peeling technologies. “All the patents and awards are in recognition of our sincere efforts in innovation. We are proud to say that all of these technologies were born out of countless failures and ideas that were put into storage.” Ryo concluded.

ASTRA Inc.

Mr. Ryo Takeshita

Tel.: +81 0245412444

E-mail: ryo@e-astra.co.jp

Website: https://peel-a-ton.com/