The cost of shipping is rising, there is a shortage of shipping containers, and the Covid-19 pandemic is still raging. These external factors have had an enormous impact on the Chinese fruit and vegetable industries in the last two years.

Emerson Electric, one of the leading companies in the research, development, and retail of thermometers, provides monitoring solutions for fresh fruit and vegetable distribution across the globe. Mr. Zeng Dang, Head of Commercial and Residential Solutions as well as Cold Supply Chain Services, recently talked about some of their latest products and shared his insight in the positive and negative consequences of external factors for the company.

"The product assortment is diverse, and our services cover a broad area"

Mr. Zeng Dang first talked about the unique advantages of Emerson Electronics. "There are not that many global thermometer brands, and an even smaller number of companies provides services for the entire cold supply chain from beginning to end," said Director Zeng. "Our greatest strength is the ability to provide comprehensive monitoring solutions for the entire cold supply chain. Emerson products provide services every segment of the cold supply chain from the production area to the table, such as compressors for cold storage in fruit and vegetable production areas, refrigeration valves, and controllers, as well as collective monitoring systems for use in fruit and vegetable distribution centers and wholesale markets, or freezing units and AI systems for supermarkets and fruit shops. We offer comprehensive, integrated solutions for every segment of the supply chain, and provide multidimensional services for clients in the fruit and vegetable industries. And one of the most important aspects of the cold supply chain is the ability to monitor and control temperature."

"Our services cover a broad area and support a large number of clients, which means that our post-retail services have to meet high requirements. Emerson Electronics is a global company and owns retail and technology support centers in key areas all over the world. Not many companies offer cross-border services and local tech support," said Director Zeng. "For example, our Oversight platforms supports 13 different languages. This multilingual support forms the backbone of our global service system, but in addition we also work on our soft power. Our local teams often visit clients in the region. They provide services, and study the client to better grow together."

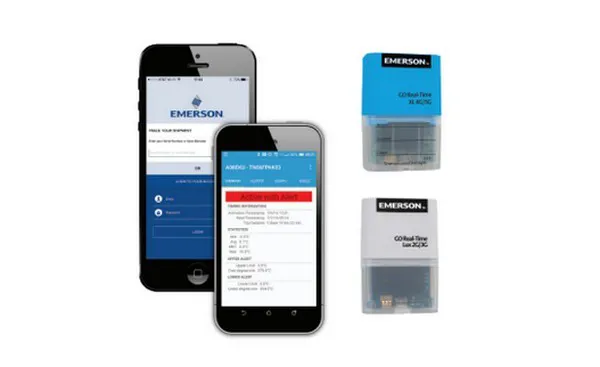

"Although we have a wide range of products, they broadly fall into one of two categories," said Director Zeng. "The first category is what we call 'XPRESS PDF', a recording solution that begins when products are dispatched and automatically records temperature data in transit. This data can be downloaded onto a computer via USB technology and then compiled into a pdf. The quality-price ratio of such solutions is relatively high. This solution is generally used for dragon fruit, bananas, garlic, and other low-value products. The second solution is what we call 'GO LUX'. This solution offers real-time monitoring solutions. Clients use software on their phone or computer to track the location and temperature of their products in real time. The 'GO LUX' solution is often the preferred choice for delicate, high-value products such as blueberries or the more expensive cherries."

Impact of rising shipping costs and the pandemic on fruit and vegetable trade

There has been a shortage of shipping containers since October last year and many ports around the world experience back logs. According to Director Zeng: "One of the consequences we have seen is an uptick in the sales of real-time monitoring solutions. Clients more often opt for real-time monitoring products because they urgently want to know what is happening to their products. They want to know whether their products are kept at the right temperature. In addition, we now offer products with a battery life of 30, 60, or 90 days. This gives our clients the flexibility to respond to delays in port and extended shipping periods. One of the negative aspects we encounter is the severe shortage of shipping containers in many countries, which means that many of our clients simply can not dispatch their products, and that brings the sales of temperature control products to a standstill."

Director Zeng also talked about the impact of the pandemic on the fruit and vegetable trade. "The use of temperature control products was already on the rise in the years prior to the outbreak of Covid-19, but the pandemic did hasten this development. Where many companies used to judge product quality on the basis of experience, the pandemic stimulates the use of IoT and long-distance trade data," said Director Zeng.

"People are more isolated because of the pandemic. They interact less. Instead, people in the fruit and vegetable industries have to rely on large amounts of data concerned with the temperature of products in every segment of the cold supply chain as the standard for product control. That is where leading companies in the fruit industry stand out. The higher up in the fruit industry a company is, the more they appreciate the value of data from every segment of the supply chain. Since this is very difficult to obtain for 'non-standard products', these companies really do deserve praise and profit. And we are more than happy to assist our clients, help them take advantage of valuable temperature data, and make the shift to proper management of real-time, long-distance monitoring solutions."

Emerson Electronics will participate in the (delayed) Shanghai International Fruit Expo. "It seems that whatever fruit you sell in 2021, a profit is hard to make. We hope that under these circumstances our clients and old friends are able to raise and stabilize the product quality of their fruit products. The Emerson cold supply chain team also hopes to connect with clients and old friends during the expo in Shanghai, to discuss the value of cold supply chain data, and help even more companies in the fruit trade set up their own standards for product control. Together with our clients we face the challenges in the industry, and we hope to provide an even larger number of top-quality monitoring solutions, so that together with our clients we can guarantee the product quality and freshness of fruit in the Chinese market."

For more information:

Yu Hailin

Emerson Electronics

E-mail: [email protected]

Tel.: 021-33387307

Tel.: 13701763737